About Us

Work Together,Do The Best

――――― Excellent Products Skill and Customer Service

We specialize in manufacturing of LED lighting and audio products. Our main products include stage light, wedding lights, wall wash lighting, LED panel lights, LED neon light, LED pillar lights, solar lighting,LED string lights, architectural lighting, mushroom lights and holiday lighting and pro power amplifiers.

In our over 20 years of supplying high-quality products, our team’s excellent work and professional service have earned us a lot of praise from our clients and a very good reputation in these fields.

Your Reliable Partner

――――― Credible Experience in Manufacturing Quality Products

We are a customer-centric company that focuses on affordable, environment-friendly, long lifetime products. As an obligate and trusted partner in developing superior audio and lighting system products, we provide OEM service to help our customers grow their business in their area.

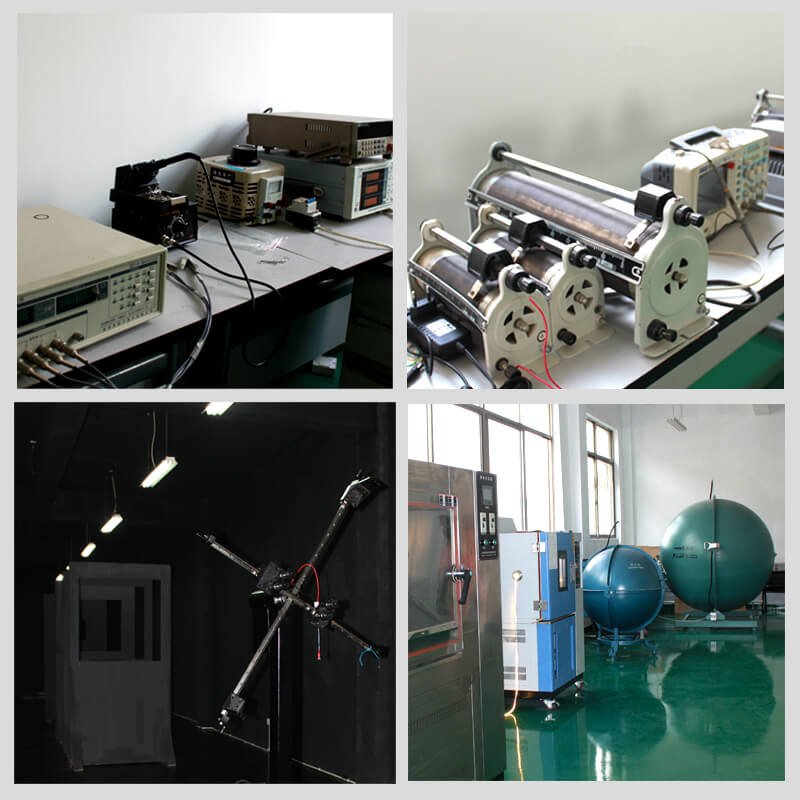

As an ISO 9001:2015 manufacturer of power amplifiers and LED lighting products, we have complete laboratory testers and manufacturing facilities to ensure the products are safe and excellent.

Manufacturing Process

――――― Manufacturing The Right Products for You

Die Design

Our experienced designer team offer customized 3D mold simulation,CNC machining and plastic injection service.

Trial-production

Before bulk producing,do the small quantity trial manufacturing for new products and evaluate the total quality .

Testing

Test all trial manufacturing products make sure the photoelectric and physical parameters meet with design requirement.

Bulk-production

Evaluate all trial manufacturing products meet with requirement then allow to manufacture in bulk.Do the in process inspection during manufacturing.

Inspection

After aging all products,do the finished products quality inspection according to the requirement of sampling rate and frequency.

Quality Control

――――― Professional QC Team Ensure Strict Quality Control for All Procedures

Component Inspection

All components must be incoming test and warehouse-out inspection make sure each one is eligible.

Process Inspection

Each assembling procedure has QC team make sure only eligible semi-products deliver to next procedure.

Finished product Inspection

Testing finished product parameters and check the physical functions ensure all data meet with client’s requirement.

Packing Inspection

Inspecting the packing detail and verifying the drop test make sure the packing fit for all kinds of transportation.

After sales tracking

Defect production complain tracking procedure make sure the corrective actions deliver to related workers directly.

Why Us

――――― All is Easy and Take Care of Everything for You

OEM&ODM

Our experienced R&D team offer customized products service for your special needs include 3D print,CAD and Pro-E design.

Customer Experience

Service of customer first,we take care of all personalized requirements from you.

Well-known Components

The global supply chain allows us to use top quality components such as Cree,Osram,Philips,Samsung and Meanwell.

Long lifetime

Our complete manufacture and test facilities ensure the products durable and exceed the normal warranty of statutory periods.

Affordable Price

Tell us your parameter requirement and personalized needs,flexible prices are available base on different market needs.

Optimized Solution

Our experienced team offer optimized solution ensure the project planning and products are marketable and advantaged.